Download Anycubic Slicer – Precision 3D Printing Made Easy!

Get the official Anycubic Slicer for seamless slicing, advanced print settings, and flawless 3D models. Optimize your prints with precision, speed, and reliability. Download now and bring your designs to life!

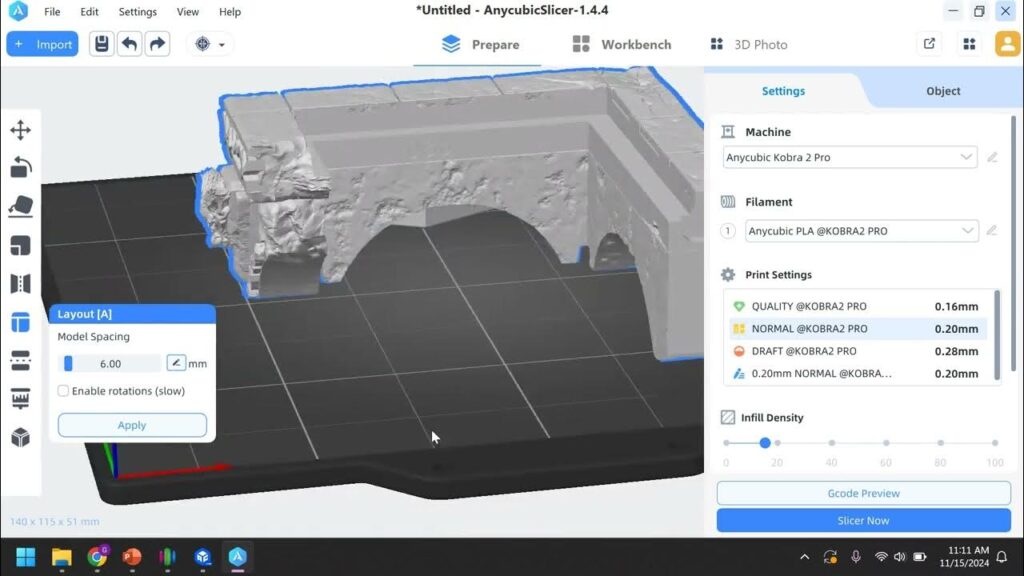

Anycubic Slicer is a powerful slicing software developed by Anycubic, a leading manufacturer of 3D printers. This software plays a critical role in preparing 3D models for printing by converting digital 3D models into G-code instructions that 3D printers can interpret. Designed specifically to complement Anycubic’s range of FDM and resin 3D printers, the slicer enhances print quality, efficiency, and overall user experience.

What is Anycubic Slicer?

Anycubic Slicer is a proprietary slicing software tailored to work seamlessly with Anycubic 3D printers. It allows users to fine-tune print settings, such as layer height, print speed, temperature, and support structures, before sending the instructions to the printer. The software simplifies the process of preparing models for both FDM (Fused Deposition Modeling) and resin-based SLA (Stereolithography) printers, making it a versatile option for different printing technologies.

Key Features

Following are the key features of the Anycubic Slicer:

- Optimized for Anycubic Printers

Anycubic Slicer is specifically designed for Anycubic 3D printers, ensuring seamless communication and optimal performance. Unlike third-party slicers, it comes preloaded with printer-specific profiles, reducing the need for manual adjustments. This level of integration minimizes errors, enhances print success rates, and ensures that users get the best possible output from their Anycubic machines. It also supports firmware updates, further improving the functionality and reliability of Anycubic printers over time. By eliminating compatibility issues and optimizing machine-specific parameters, Anycubic Slicer ensures a smooth and efficient printing process. - User-Friendly Interface

The software features an intuitive and easy-to-navigate user interface, making it accessible to both beginners and experienced users. It offers a clean layout with well-organized menus and settings, ensuring that users can quickly locate and adjust parameters without confusion. The interface also includes tooltips and guidance for common settings, allowing even novice users to start slicing models without a steep learning curve. Additionally, dark and light mode options improve visual comfort during long slicing sessions. The software’s interface design focuses on simplicity while still offering advanced options for users who want greater control over their prints. - Customizable Print Settings

Anycubic Slicer allows users to fine-tune numerous print parameters to optimize their 3D prints. Key adjustable settings include:- Layer Height: Defines the print resolution, with thinner layers providing more detail and thicker layers speeding up prints.

- Print Speed: Controls how fast the print head moves, balancing quality and efficiency.

- Temperature Settings: Adjusts the hotend and heated bed temperatures for different materials.

- Infill Density and Patterns: Determines the internal structure of the print, affecting strength and material usage.

- Support Structures: Provides options for auto-generating supports for overhangs and complex geometries.

- Retraction Settings: Helps reduce stringing by controlling filament pullback during non-printing moves.

- Brim and Raft Settings: Improves bed adhesion for prints that have small contact areas with the print bed. These settings allow users to tailor their prints to achieve the desired balance of quality, durability, and speed. Advanced users can create custom profiles for different filament types, ensuring repeatable, high-quality results across multiple prints.

- Resin and FDM Printing Support

Unlike many slicers that specialize in either filament or resin printing, Anycubic Slicer supports both technologies. This makes it an all-in-one solution for users with multiple Anycubic printers. For FDM printers, it provides robust slicing settings tailored for materials like PLA, ABS, PETG, and TPU. For resin-based SLA printers, it offers settings to fine-tune exposure times, layer curing, and support placements. The ability to switch between FDM and SLA slicing within the same software simplifies workflow and improves productivity for users handling different types of prints. It also ensures that users can explore different printing technologies without needing to learn multiple software applications. - Auto-Support Generation

When printing complex models with overhangs, supports are crucial for successful prints. Anycubic Slicer includes an intelligent auto-support feature that detects overhanging parts and generates necessary supports to prevent print failures. Users can adjust the density, contact points, and positioning of these supports to minimize post-processing work. Additionally, for resin prints, it ensures that delicate structures are adequately supported to prevent detachment during printing. Manual support placement is also available, giving users full control over support structures for highly detailed models. - Preview Mode

The software provides an advanced preview function that displays a layer-by-layer visualization of the sliced model. This feature allows users to inspect how each layer will be printed, identify potential issues, and make adjustments before starting the print. The preview includes options to visualize support structures, infill patterns, and material flow, ensuring that users have complete control over the final output. This real-time preview is particularly useful for optimizing print times and detecting errors early. The preview also includes estimated print time and material usage calculations, helping users plan their prints efficiently. - STL and OBJ File Compatibility

Anycubic Slicer supports widely used 3D model file formats, including STL and OBJ. This compatibility ensures seamless integration with various 3D modeling software, such as Blender, Tinkercad, Fusion 360, and ZBrush. Users can import models directly into the slicer, apply transformations (scaling, rotating, mirroring), and optimize them for printing without needing additional software. This flexibility makes it a convenient tool for hobbyists, engineers, and professionals working with different design workflows. File repair features also help fix common issues such as non-manifold edges or holes in models before slicing.

Download Anycubic Slicer Next

Download Anycubic Slicer

Getting Started with Anycubic Slicer

- Downloading and Installing the Software

- Download the latest version of Anycubic Slicer.

- Choose the appropriate version for your operating system (Windows or macOS) and follow the installation prompts.

- Once installed, launch the software and ensure it recognizes your Anycubic printer.

- Check for updates regularly to ensure you have the latest features and optimizations.

- Importing a 3D Model

- Click on the “Import” button to load an STL or OBJ file into the slicer.

- The model will appear on the virtual print bed, where you can adjust its position, scale, and orientation.

- Use the auto-orient feature to position the model for optimal printability.

- Configuring Print Settings

- Select your printer model from the predefined list to automatically apply optimized settings.

- Adjust key parameters like layer height, infill density, support generation, and print speed based on your desired print quality and material.

- For resin printers, configure exposure time, bottom layer count, and lifting speed for the best results.

- Use profile saving options to create presets for different filaments and resins.

- Slicing the Model

- Click the “Slice” button to process the model and generate the necessary G-code instructions.

- Review the layer-by-layer preview to identify any potential issues before exporting the file.

- Check estimated print time and material usage to optimize efficiency.

- Saving and Printing the Model

- Save the G-code file to an SD card or transfer it directly to the printer via USB or Wi-Fi (if supported).

- Insert the SD card into your printer and start the print job.

- Ensure the print bed is properly leveled before starting the print.

- Monitoring and Troubleshooting

- Monitor the first few layers of the print to ensure proper adhesion and consistency.

- If any issues arise, adjust settings in Anycubic Slicer and re-slice the model for better results.

- Use Anycubic Slicer’s built-in troubleshooting guide for common printing problems.